Globe Valve

OS & Y Type, Rising Stem, Bolted Bonnet ASA / ND Design Controls Globe Valves are Outside Screw, Rising Stem, Bolted Bonnet Construction, threads are away from the line fluid and easy to lubricate. Globe Valves are generally available with Plug Type Disc, which is designed to give leak tight seating over a long period of in built wear life. Globe valves body seat ring is shoulder type, threaded body seat ring which has large taper area that is for ample seating. Two nos. slots are provided on body seat ring, which is for easy removal for servicing at site. Welded type seat ring & Integral seat ring are also available in. Globe Valve. All Globe Valve stem is made from solid one piece construction. The yoke bush of Globe Valve has a long thread engagement for accurate stem alignment. The standard range of J. D. Globe Valve in sizes of up to 12 (300mm) Globe Valve (ASA Design), OS & Y Type, Rising Stem, Bolted Bonnet Design Standard: BS 1873 Size Range - 1" to 12" Pressure Rating - 125# / 150# / 300# End Connection Flanged End Globe Valve (ND Design) OS & Y Type, Rising Stem, Bolted Bonnet Design Standard: ND, DIN Standard Size Range: 1" to 12" Pressure Rating: PN 6 / PN 10 / PN 16 / PN 25 / PN 40 End Connection Flanged End Forged Steel Globe Valve OS & Y Type, Rising Stem, Bolted Bonnet Design Standard: BS 5352 Pressure Rating: 800# / 1500# End Connection : Screwed / Socket Weld / Butt Weld End

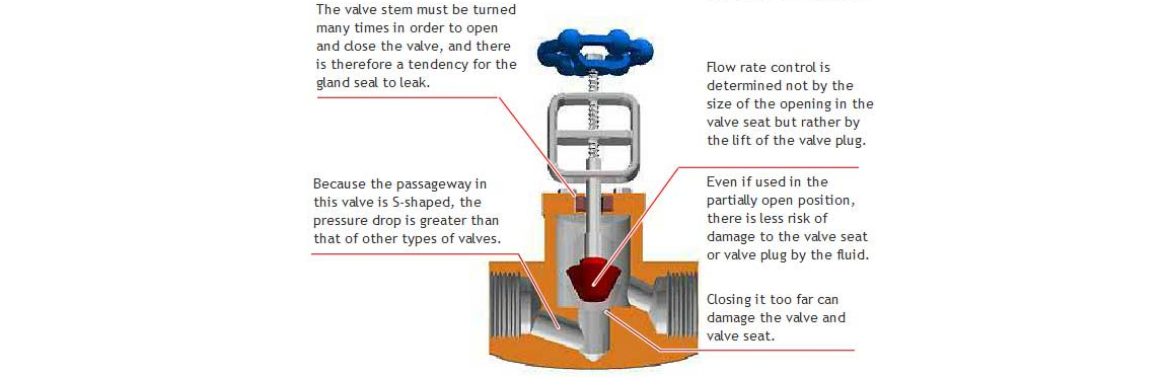

Salient Features : Body & Bonnet made from high quality casting with liberal sections. The castings are precision machined for high performance Rising Stem & Rising Hand Wheel Construction. Die moulded Graphite (Grafoil) Packing Rings, controlled clearance between stem, gland and bonnet bushing for guaranteed low emissions and also suitable for higher temperature. Deep stuffing box is providing for tightness and maximum long packing life. Swinging Eye Bolts facilitate easy access to the stuffing box. Back seating feature facilitates repacking of the stuffing box on line with the valve in fully open position. Seat Ring Screwed in to the body (Replaceable Type) or integral type. Stellited Disc, Seat Ring & Back Seat can also be offered on special request. Higher Pressure & Higher Size Valves are provided with Thrust Bearings and also with Gear drive arrangements. Material of Construction: Cast Iron : IS 210 Gr FG 200 Cast Carbon Steel : ASTM A 216 Gr WCB Cast Stainless Steel : ASTM A 351 Gr CF 8/CF 8M Forged Carbon Steel : ASTM A 105 Forged Stainless Steel : ASTM A 182 Gr F304 / F316 End Connection : Screwed AS PER BSP/BSPT/NPT Socketweld : AS PER ANSI B 16.11 Flanged : AS PER ANSI B 16.5 Pressure Rating : ASA 125#, 150#, 300#, 600#, 800#, PN 16 & PN 40 Engineering Option : Gear Operated, Electrical Actuated, Size Range : 15mm to 300 mm Design & Testing International Standard: Valve Design : BS 5351 / ANSI B 16.34 / API 6D Pressure Testing : BS 6755-I Face To Face : ANSI B 16.10 Flange Drilling : ANSI B 16.5 / BS 10 Table / DIN / IS 6392 Butt Weld End : ANSI B 16.25 Socket Weld End : ANSI B 16.11 Screwed End : ANSI B 1.20.1(BSP/NPT) Special Options : Angle & Y Type Design Available Parabolic, Regulating, Guided & Soft Seating Disc (Plug) available Extended Bonnet design for low temperature and cryogenic services. Gland Seal Design (Water Seal) With Lantern Ring Non-Rising Hand Wheel on special request Bolted Bonnet / Pressure Seal Bonnet Gear / Pneumatic Cylinder / Electrical Actuator Operated Locking Arrangement With NACE MR 0175 Tailor Made Valve