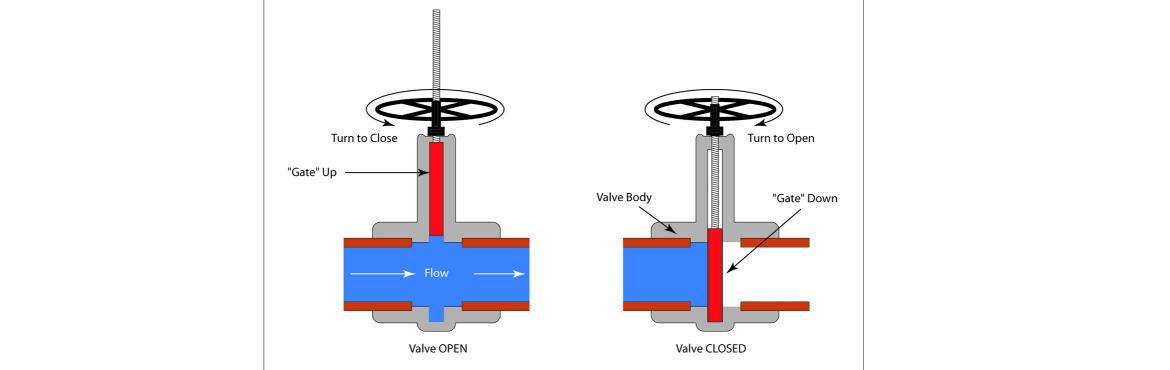

Gate Valve

Gate valves have an extended use in the petrochemical industry due to the fact that they can work with metal-metal sealing. They are used in clean flows. When the valve is fully opened, the free valve area coincides with area of the pipe, therefore the head lose of the valve is small. This valve is not recommended to regulate or throttling service since the closure member could be eroded. Partially opened the valve can vibrate. Opening and closing operations are slow. Due to the high friction wear their use is not recommend their use in often required openings. This valve requires big actuators which have difficult automation. They are not easy to repair on site. Types of gate valve: -Casting steel gate valve - Forged steel gate valve Casting Steel Gate Valve OS & Y Type, Rising Stem, Bolted Bonnet Design Standard: API 600 Size Range - 1" to 12" Pressure Rating - 125# / 150# / 300# End Connection Flanged End Forged Steel Gate Valve OS & Y Type, Rising Stem, Bolted Bonnet Design Standard: API 602 Pressure Rating: 800# / 1500# End Connection : Screwed / Socket Weld / Butt Weld End

Salient Features :

Body & Bonnet made from high quality casting with liberal sections. The castings are precision machined for high performance

Bi-Directional Shut-Off

Die moulded Graphite (Grafoil) Packing Rings, controlled clearance between stem, gland and bonnet bushing for guaranteed low emissions and also suitable for higher temperature.

Deep stuffing box is providing for tightness and maximum long packing life.

Swinging Eye Bolts facilitate easy access to the stuffing box.

Back seating feature facilitates repacking of the stuffing box on line with the valve in fully open position.

Seat Ring Screwed in to the body are replaceable type. Seal welded type Seat Ring & Integral Seat cab also be offered on special request.

Stellited Disc, Seat Ring & Back Seat can also be offered on special request.

Higher Pressure & Higher Size Valves are provided with Thrust Bearings and also with Gear drive arrangements.

In built wear life for long duration of service.

Material of Construction: Cast Iron : IS 210 Gr FG 200 Cast Carbon Steel : ASTM A 216 Gr WCB Cast Stainless Steel : ASTM A 351 Gr CF 8/CF 8M Forged Carbon Steel : ASTM A 105 Forged Stainless Steel : ASTM A 182 Gr F304 / F316 End Connection : Screwed AS PER BSP/BSPT/NPT Socketweld : AS PER ANSI B 16.11 Flanged : AS PER ANSI B 16.5 Pressure Rating : ASA 125#, 150#, 300#, 600#, 800# Engineering Option : Gear Operated, Electrical Actuated, Size Range : 15 mm to 300 mm

Design & Testing International Standard: Valve Design : API 600 / API 602 / API 603 / IS 780 / BS 14846 Pressure Testing : API 598 Face To Face : ANSI B 16.10 Flange Drilling : ANSI B 16.5 / BS 10 Table / DIN / IS 6392 Butt Weld End : ANSI B 16.25 Socket Weld End : ANSI B 16.11 Screwed End : ANSI B 1.20.1(BSP/NPT)

Special Options :

Extended Bonnet design for low temperature and cryogenic services.

Flexible / Solid Wedge / Double Disc Type

Gland Seal Design (Water Seal) With Lantern Ring

Bolted Bonnet / Pressure Seal Bonnet

Gear / Pneumatic Cylinder / Hydraulic Cylinder / Electrical Actuator Operated

Locking Arrangement

With NACE MR 0175

Tailor Made Valve